Prefabricated Steel Structure Workshop

Brand MEITUO

Product origin China

1. Prefabricated steel workshops have low costs, with unit prices ranging from $25/m2 to $75/m2 depending on customer requirements.

2. The width of steel structure workshops can reach 150 feet to 250 feet.

3. Prefab metal shop buildings can provide customized services.

Introduction to prefabricated steel workshop:

Steel structure workshop is a kind of building with high-strength steel as the main structure. Our prefab metal shop buildings will produce the main components such as columns, beams, roof trusses, purlins in advance in the factory, and then transport them to the construction site for rapid assembly, shortening the construction period. Prefabricated steel structure frame workshop is usually equipped with complete systems such as insulation, ventilation, drainage, fire protection, etc. To ensure a safe, comfortable and efficient working environment inside the workshop.

Advantages of prefabricated steel workshop:

1. Our steel structure workshop has high strength and stability, can withstand natural disasters such as earthquakes and typhoons, and is suitable for use in areas with complex geological conditions or changeable climates.

2. The prefab metal shop buildings we produce can achieve a large-span column-free design, maximize the use of internal available space, facilitate the layout of production lines, storage areas or large equipment, and improve the overall efficiency of the workshop.

3. Our prefabricated steel structure frame workshop is scalable. It can meet the needs of expanding production scale or changing functional requirements.

Steel structure workshop parameters:

| Structure | Material | Details | |

| Main Structure | Frame Columns and Beams | Q235/Q355 | |

| End Wall Column | Q235/Q355 | ||

| H-beam welding(columns and beams) | Automatic Submerged Arc Welding | ||

| Rust Removal | Shot Blasting | ||

| Surface Processing | Alkyd Paint/Epoxy Zinc Rich Paint/Galvanized | ||

| High-Strength Bolt | Grade 10.9/8.8 | ||

| Common Bolt | Grade 4.8 | ||

| Secondary Structure | Flange Brace | Angle Steel | |

| Horizontal Support | Angle/Round Steel | ||

| Vertical Support | Angle/Round Steel | ||

| Tie Rod | Angle/Round Steel | ||

| Tie Bars | Round Steel/Casing/Shaped Steel | ||

| Purlin | Galvanized Z-beam/C-beam | ||

| Enclosure System | Roofing System | Roofing Materials | 360°Locking Seam System / Locking Screw System / Composite Panel Roofing / Rockwool Maintenance System |

| Daylighting Band | FRP Plate | ||

| Gutter (inside/outside) | Stainless Steel/Colored Steel Plate | ||

| Rain Pipe | PVC Pipe/Color Steel Rainwater Pipe | ||

| Wall System | Wall Materials | Locking Screw System / Composite Panel Wall / Rockwool Maintenance System | |

| Accessories | Sealant, Self-tapping Self-drilling Screws, etc. | ||

| Edge Flashing | Color Plate/Stainless Steel | ||

| Others | Ventilator | Powered/Unpowered Axial Flow Ventilators | Customizable |

| Ventilation Tower | Finished Product | Customizable | |

| Door | Electric Rolling Door/Sliding Door/fireproof door | Customizable | |

| Window | Aluminum Alloy/plastic Steel Window/Fireproof Window | Customizable | |

Construction process of prefabricated steel workshop:

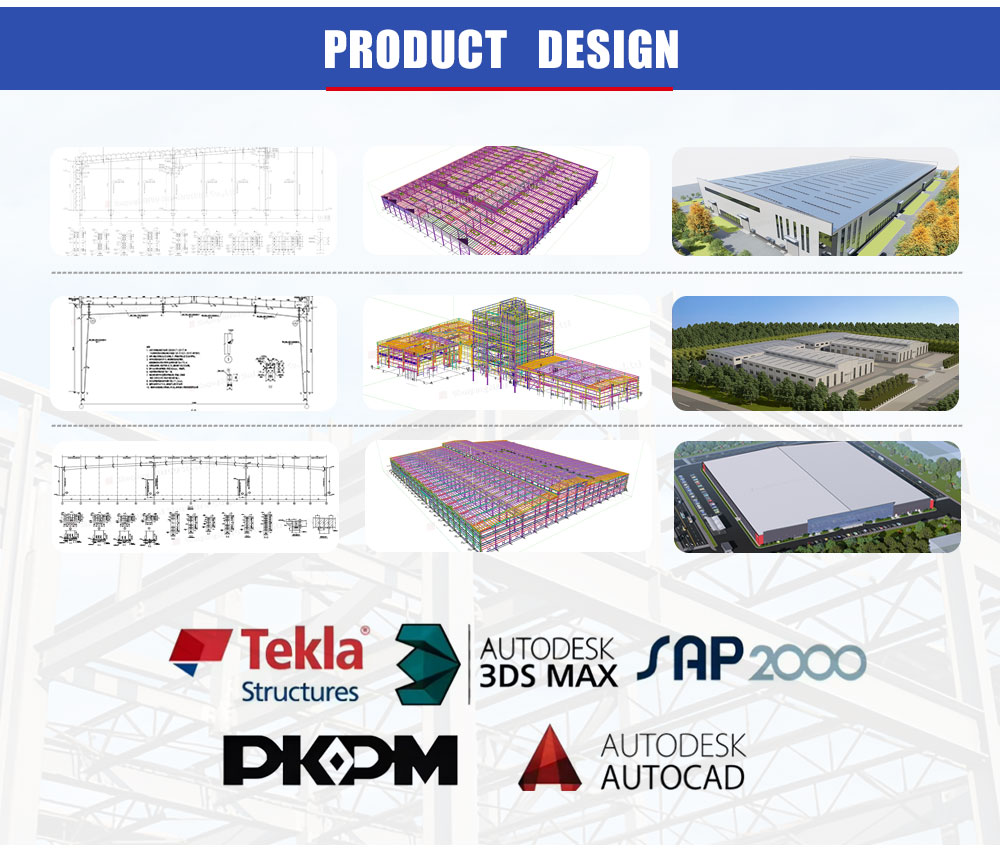

The steel structure workshop we produce is generally divided into 6 stages. According to customer needs and site conditions, 3D renderings are provided. Then the prefab metal shop buildings are prefabricated in the factory, and processed into standardized components through cnc cutting, automatic assembly, robot welding and other processes to ensure a 100% qualified rate. Then the foundation construction of the prefabricated steel structure frame workshop is carried out. After completion, the on-site installation and enclosure system construction are carried out, and finally acceptance and delivery are carried out.

FAQ:

1. What industries are prefabricated steel workshops suitable for?

Steel structure workshops are suitable for production workshops, logistics warehouses, food processing plants, electronic manufacturing plants and other fields.

2. How many years are the service life of prefab metal shop buildings?

Prefabricated steel structure frame workshop generally has a service life of more than 50 years.

3. Is the maintenance cost of prefab metal shop buildings high?

Our prefabricated steel workshop has high structural durability and low later maintenance costs.

After-sales service of prefabricated steel workshop:

Meituo provides comprehensive and professional after-sales service for prefabricated steel structure workshop. From the beginning of project delivery, we will provide steel structure workshop with detailed installation guidance documents and construction technical support to ensure that customers can successfully complete on-site assembly. For customers in need, we can also arrange professional technicians to provide remote guidance. We promise that the main structure, roof, wall materials and supporting systems of prefabricated steel structure workshop also enjoy a certain number of years of warranty policy, which will be clearly stated according to the material type. During the use of prefab metal shop buildings, if customers encounter any maintenance, repair or expansion problems, we will provide fast-response technical consultation and solutions to help customers deal with them in a timely manner and reduce downtime.

Uses of prefabricated steel workshop:

Steel structure workshop is widely used in various industrial and commercial fields. It can be used as a production workshop in the manufacturing industry and is suitable for industries such as mechanical processing, equipment assembly, electronic manufacturing, and automobile parts production. It meets the needs of large-space column-free, high-load-bearing, and flexible partitioning operations. In the field of warehousing and logistics, prefab metal shop buildings can be used as large warehouses, distribution centers, and cold chain warehouses to provide a safe, dry, and environmentally controlled material storage environment, effectively improving logistics efficiency; in agriculture and animal husbandry, it can be used as agricultural product processing workshops, feed plants, and agricultural machinery storage warehouses to meet the requirements of efficient processing and preservation of agricultural products. Our prefabricated steel structure frame workshop can also be used in scenes such as equipment maintenance workshops, auxiliary buildings of power plants, and water treatment facility plants in the energy and environmental protection industries.

Why choose prefabricated steel workshop?

Our steel structure workshop adopts modular design, with short construction time and can be put into use more quickly. In addition, the steel materials of prefab metal shop buildings we produce can be recycled, which conforms to the concept of green development and can reduce the cost of later maintenance to a certain extent. According to the different needs of customers, we can provide customized services to make prefabricated steel structure frame workshop meet your needs.

Packaging and transportation of prefabricated steel workshop:

Large steel components of steel structure workshop are usually fixed with customized pallets, and protected by waterproof film, steel strapping and other protective measures. Small components are packed in special wooden boxes or iron frames, which are clearly classified and easy to unload and manage on site. We can provide a variety of methods such as sea container transportation, bulk transportation or multimodal transportation according to the different needs of the project, and prepare detailed packing lists and installation drawings for customers to ensure that the goods can be quickly put into storage after arriving at the site, thereby improving the overall construction efficiency.

About us:

Meituo has professional CNC automated steel structure production equipment and assembly line steel structure processing facilities, including H-beam CNC flame feeder, heavy H-beam assembly machine, gantry submerged arc welding, mechanical straightening machine, CNC surface drilling, through-type shot blasting machine and other CNC H-beam production lines, which can meet different customer needs.