Prefab Factory Workshop

Brand MEITUO

Product origin China

1. The service life of prefab metal structure workshop is up to 50 years.

2. All components of steel structure metal prefab workshop are prefabricated in the factory to speed up the construction.

3. Steel structure prefabricated workshop can provide customized services according to actual needs.

Introduction to prefab metal structure workshop:

Metal structure workshop is a form of industrial building with steel structure as the main body, which is prefabricated in the factory and assembled on site. Our steel structure metal prefab workshop uses high-strength steel as the main frame structure. The walls and roofs can be made of color steel sandwich panels, single-layer color steel plates or other environmentally friendly materials according to needs, which can ensure the durability and aesthetics of the building. The steel structure prefabricated workshop we produce can be customized with workshop size, floor height, load requirements, crane track layout, etc. To meet the use requirements of the scene. In addition, our prefab metal structure workshop is highly flexible and can be applied to multiple industries such as mechanical processing, equipment manufacturing, food processing, and textile production.

Advantages of steel structure metal prefab workshop:

1. Our steel structure prefabricated workshop adopts modular prefabrication design. All main components are produced in the factory with high precision and small error, which can ensure product quality. And our prefab metal structure workshop usually only takes a few weeks to complete the main structure construction and can be put into use quickly.

2. Our metal structure workshop optimizes the structural layout, adopts standardized components, reduces manual on-site operations, etc., so that the overall construction cost is lower and the later maintenance cost is less, which can maximize the return on investment.

3. The internal space design of steel structure metal prefab workshop is extremely flexible, which can achieve large spans and no intermediate column support. It is particularly suitable for placing large equipment or building multiple production lines to improve space utilization.

4. According to actual needs, the steel structure prefabricated workshop we produce can also customize supporting facilities such as crane beams, insulation systems, ventilation systems, drainage systems, etc. To improve convenience and comfort.

Parameters of prefab metal structure workshop:

| Structure | Material | Details | |

| Main Structure | Frame Columns and Beams | Q235/Q355 | |

| End Wall Column | Q235/Q355 | ||

| H-beam welding(columns and beams) | Automatic Submerged Arc Welding | ||

| Rust Removal | Shot Blasting | ||

| Surface Processing | Alkyd Paint/Epoxy Zinc Rich Paint/Galvanized | ||

| High-Strength Bolt | Grade 10.9/8.8 | ||

| Common Bolt | Grade 4.8 | ||

| Secondary Structure | Flange Brace | Angle Steel | |

| Horizontal Support | Angle/Round Steel | ||

| Vertical Support | Angle/Round Steel | ||

| Tie Rod | Angle/Round Steel | ||

| Tie Bars | Round Steel/Casing/Shaped Steel | ||

| Purlin | Galvanized Z-beam/C-beam | ||

| Enclosure System | Roofing System | Roofing Materials | 360°Locking Seam System / Locking Screw System / Composite Panel Roofing / Rockwool Maintenance System |

| Daylighting Band | FRP Plate | ||

| Gutter (inside/outside) | Stainless Steel/Colored Steel Plate | ||

| Rain Pipe | PVC Pipe/Color Steel Rainwater Pipe | ||

| Wall System | Wall Materials | Locking Screw System / Composite Panel Wall / Rockwool Maintenance System | |

| Accessories | Sealant, Self-tapping Self-drilling Screws, etc. | ||

| Edge Flashing | Color Plate/Stainless Steel | ||

| Others | Ventilator | Powered/Unpowered Axial Flow Ventilators | Customizable |

| Ventilation Tower | Finished Product | Customizable | |

| Door | Electric Rolling Door/Sliding Door/Fireproof door | Customizable | |

| Window | Aluminum Alloy/plastic Steel Window/Fireproof Window | Customizable | |

Purpose of steel structure metal prefab workshop:

Our steel structure metal prefab workshop can be used in mechanical processing, equipment manufacturing, metal product processing, electronic assembly and other industries. It can provide spacious, column-free internal space, facilitate large equipment layout, assembly line installation and production operations, and improve overall production efficiency. The steel structure prefabricated workshop we produce can flexibly plan stacking areas, sorting areas, and loading and unloading areas according to the customer's storage needs, effectively improve warehouse management efficiency, and optimize material flow.

And our prefab metal structure workshop is also suitable for industries with high environmental requirements. It can ensure that the production environment meets hygiene standards and improve product quality. In new energy, new materials, chemical and other industries, our metal structure workshop can provide customized design services according to special production process requirements to meet high standards for flexible space layout and safety performance.

How is prefab metal structure workshop installed?

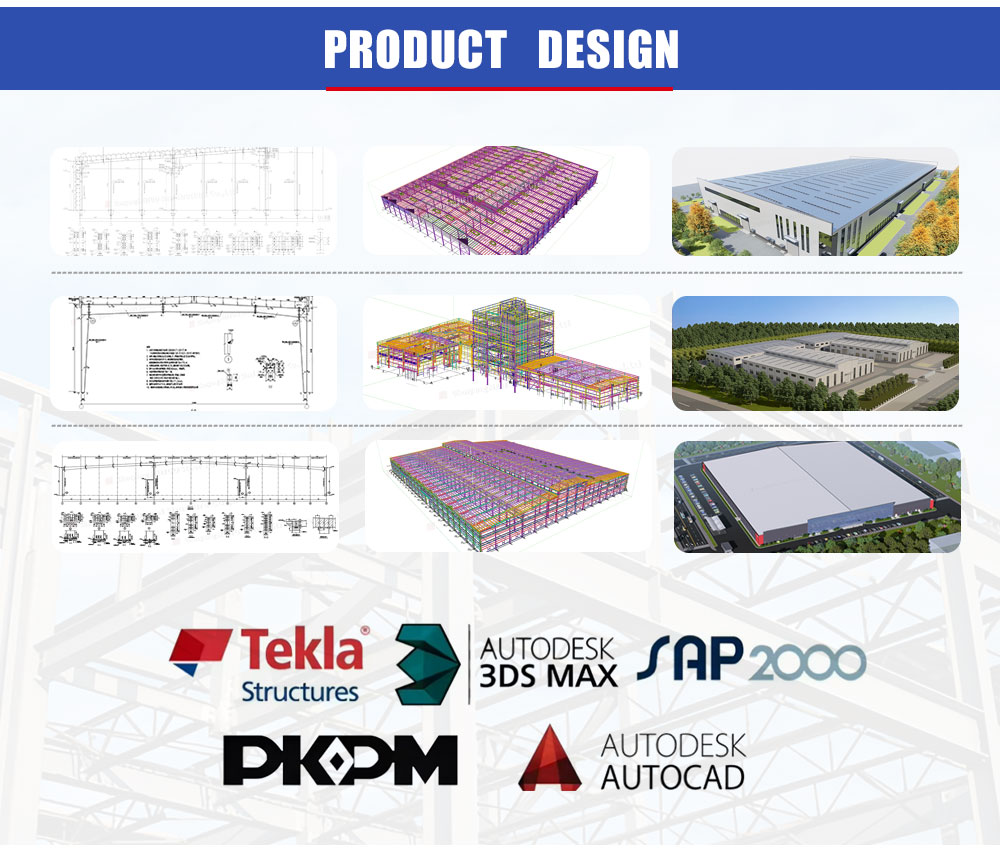

The installation process of metal structure workshop is relatively simple. Before the formal construction, we will provide steel structure metal prefab workshop detailed construction drawings and installation instructions according to the customer's project requirements and the actual site conditions. The main beams, columns, roof trusses, purlins, etc. Of steel structure prefabricated workshop are all processed in advance in the factory and strictly inspected. After being transported to the construction site, you can directly refer to the instruction manual for installation. After the foundation installation of prefab metal structure workshop is completed and accepted, the installation of the main steel structure will begin. Generally, it starts with the columns, then connects the main beams, and then gradually sets up the roof truss system. After all the installation is completed, we will conduct a detailed overall inspection of the metal structure workshop to ensure that it meets the standard requirements.

Why choose our prefab metal structure workshop?

Our steel structure metal prefab workshop reduces material waste and labor costs through standardized production and modular design. The interior of the steel structure prefabricated workshop adopts a large space without columns to enhance the overall user experience. The layout is more free and flexible. The equipment position can be adjusted or the production line can be expanded at any time according to production needs without being restricted by the building structure. Our prefab metal structure workshop has strong environmental adaptability, effectively extending the service life of the building and reducing losses caused by natural disasters.

About us:

Meituo has 3 modern intelligent steel structure production lines, more than 30 sets of corrugated plate equipment, 2 high-precision C and Z-type purlin production lines, and PIR green building composite board production lines. It also has professional CNC automated steel structure production equipment and assembly line mode steel structure processing facilities, and is experienced.