Prefabricated Steel Warehouse Building

Brand MEITUO

Product origin China

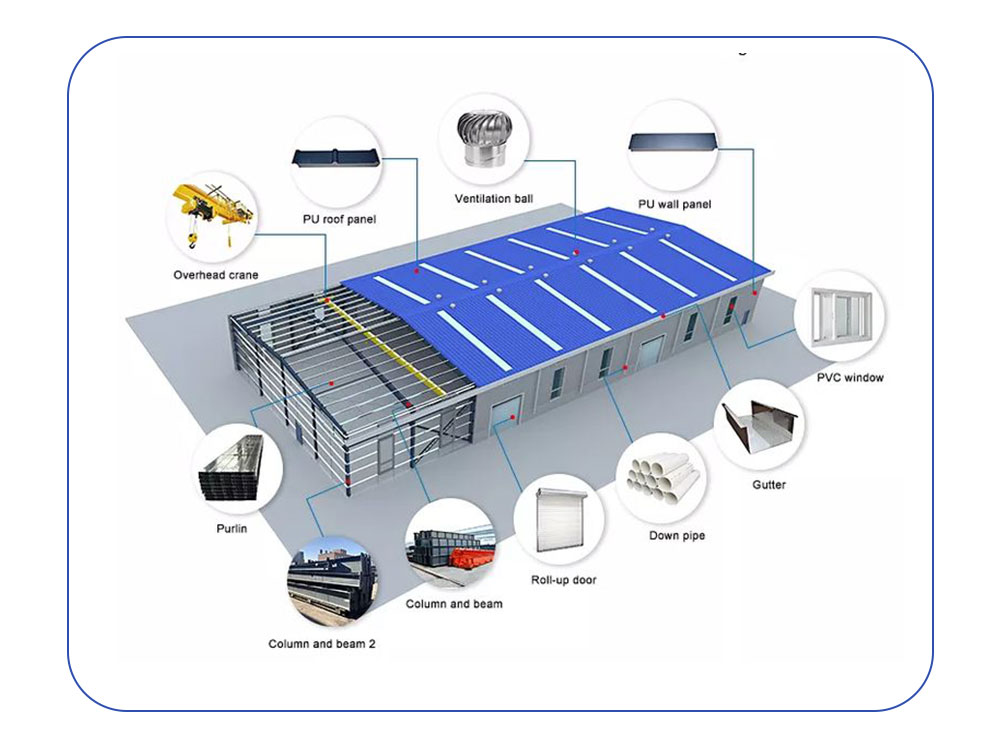

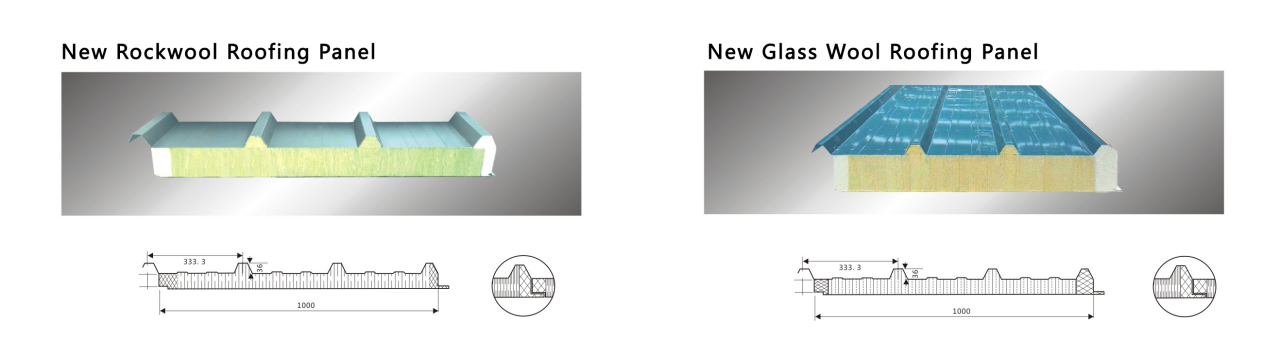

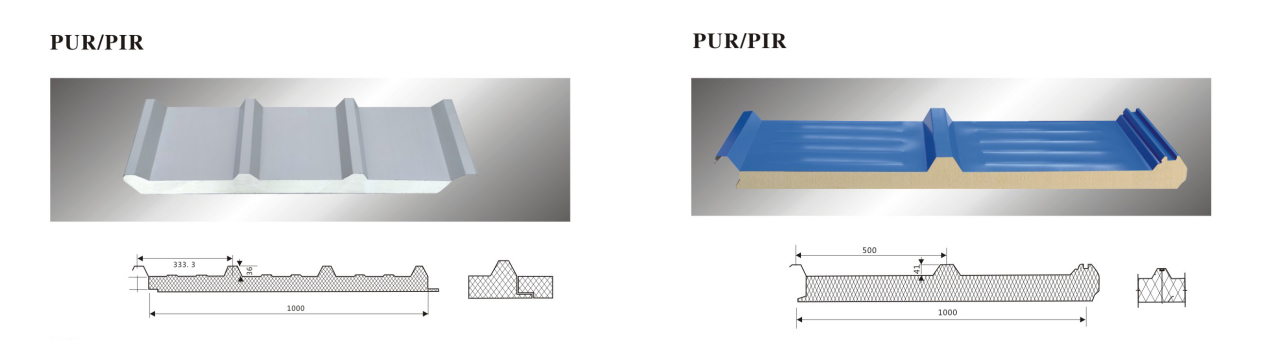

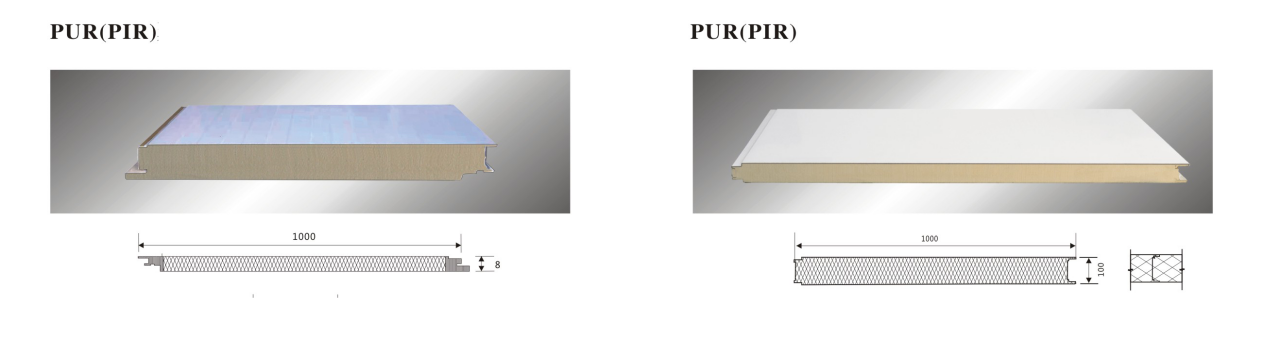

1. The Steel Frame Shed we produce has a variety of wall and roof panel options, providing a variety of materials such as color steel plates and polyurethane plates to meet different functional requirements.

2. The Steel Frame Shed we produce is suitable for various industries, including logistics, manufacturing, agriculture and other fields.

3. The Steel Frame Shed we produce can be quickly installed on site, minimizing the construction period and shortening the delivery time.

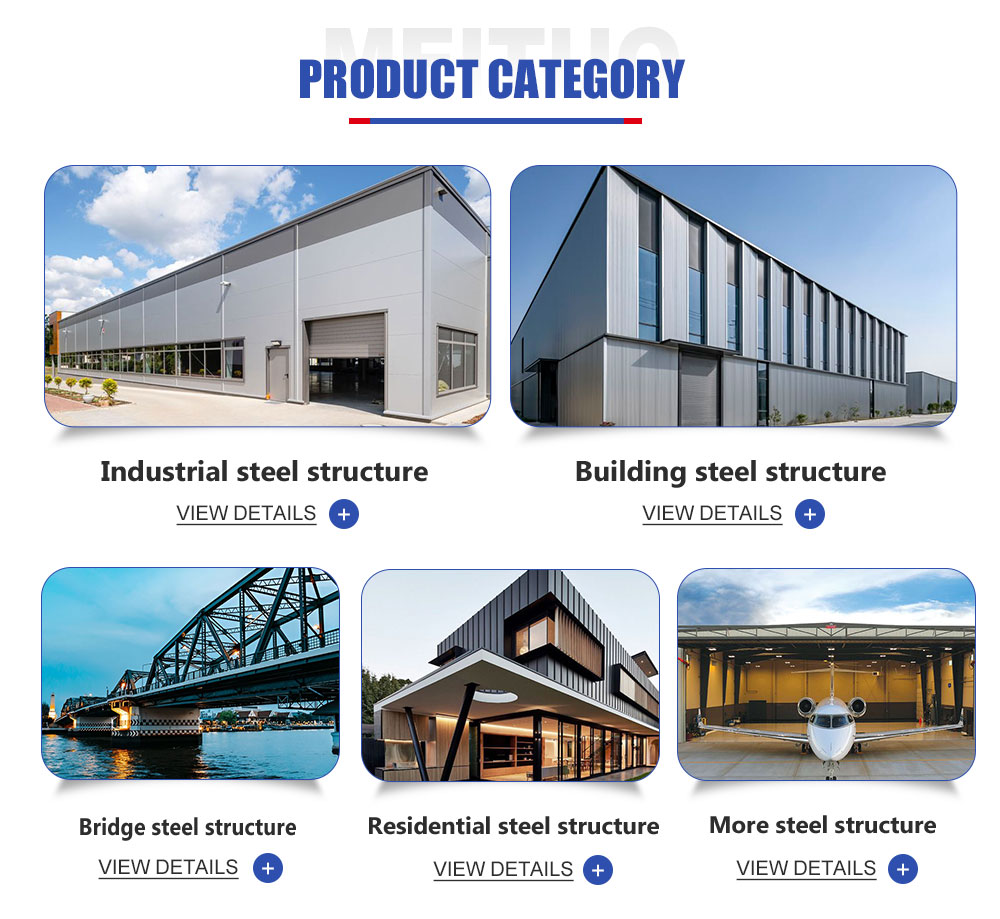

Product Introduction of Steel Frame Shed:

The Steel Frame Shed we produce has excellent wind and earthquake resistance, which makes Steel Frame Shed particularly suitable for earthquake zones or areas with frequent extreme weather. The toughness and flexibility of Steel Frame Shed enable it to withstand strong vibrations and wind, ensuring that the structure of Steel Frame Shed will not collapse or be seriously damaged due to external pressure. The anti-corrosion treated steel can effectively avoid corrosion caused by long-term exposure to bad weather, extending the service life of Steel Frame Shed. Compared with traditional concrete warehouses, the maintenance cost of Steel Frame Shed is also much lower, and customers can invest less in maintenance and repair costs.

Product advantages of Structural Steel Beam:

The steel used in our Structural Steel Beam is recyclable and environmentally friendly. The recyclability of Structural Steel Beam reduces resource waste and effectively reduces waste when the building is dismantled. The production process of Structural Steel Beam is more environmentally friendly than traditional concrete buildings because it reduces carbon emissions during the mining and transportation of building materials. For companies that focus on environmental protection, our Structural Steel Beam is a green building solution that meets the goals of sustainable development.

Product parameters of Structural Steel Beam:

Structure of Steel Frame Shed | Material of Metal Beam Frame Shed | Details of Metal Beam Frame Shed | |

Main Structure of Metal Beam Frame Shed | Frame Columns and Beams | Q235/Q355 | |

End Wall Column | Q235/Q355 | ||

H-beam welding(columns and beams) | Automatic Submerged Arc Welding | ||

Rust Removal | Shot Blasting | ||

Surface Processing | Alkyd Paint/Epoxy Zinc Rich Paint/Galvanized | ||

High-Strength Bolt | Grade 10.9/8.8 | ||

Common Bolt | Grade 4.8 | ||

Secondary Structure of Metal Beam Frame Shed | Flange Brace | Angle Steel | |

Horizontal Support | Angle/Round Steel | ||

Vertical Support | Angle/Round Steel | ||

Tie Rod | Angle/Round Steel | ||

Tie Bars | Round Steel/Casing/Shaped Steel | ||

Purlin | Galvanized Z-beam/C-beam | ||

Enclosure System | Roofing System | Roofing Materials | 360°Locking Seam System |

Daylighting Band | FRP Plate | ||

Gutter (inside/outside) | Stainless Steel/Colored Steel Plate | ||

Rain Pipe | PVC Pipe/Color Steel Rainwater Pipe | ||

Wall System | Wall Materials | Locking Screw System / Composite Panel Wall / Rockwool Maintenance System | |

Accessories | Sealant, Self-tapping Self-drilling Screws, etc. | ||

Edge Flashing | Color Plate/Stainless Steel | ||

Others | Ventilator | Powered/Unpowered Axial Flow Ventilators | Customizable |

Ventilation Tower | Finished Product | Customizable | |

Door | Electric Rolling Door/Sliding Door/Fireproof door | Customizable | |

Window | Aluminum Alloy/plastic Steel Window/Fireproof Window | Customizable | |

Logistics and packaging of Metal Beam Frame Shed:

During the Metal Beam Frame Shed transportation process, we provide customers with a variety of flexible transportation options. Depending on the destination, we will choose sea, air or rail transportation. Different transportation methods can meet the different Metal Beam Frame Shed delivery time requirements, and choose the most suitable method according to the budget to save transportation costs.

Choose a suitable location of Metal Beam Frame Shed:

The structural design and material selection of Structural Steel Beam should be determined in combination with the local natural environment. Factors such as wind load, snow load, and earthquake zone conditions will affect the overall structural safety of the warehouse. For example, sandwich panels with good thermal insulation performance should be given priority in high-cold areas, and the main structural strength and anchoring system of Structural Steel Beam should be strengthened in typhoon-prone areas. Only a Structural Steel Beam that meets local climate conditions can be more stable and durable in use.

Why choose us:

Our prefabricated Steel Structure Warehouse is designed for durability, and the specially treated materials can effectively resist the erosion of various natural environments. The service life of prefabricated Steel Structure Warehouse can be up to 50 years, and very little maintenance is required throughout the life cycle. Due to the improved corrosion resistance and wind resistance of prefabricated Steel Structure Warehouse, customers do not need to frequently repair or replace, which greatly reduces the maintenance cost of daily operations.

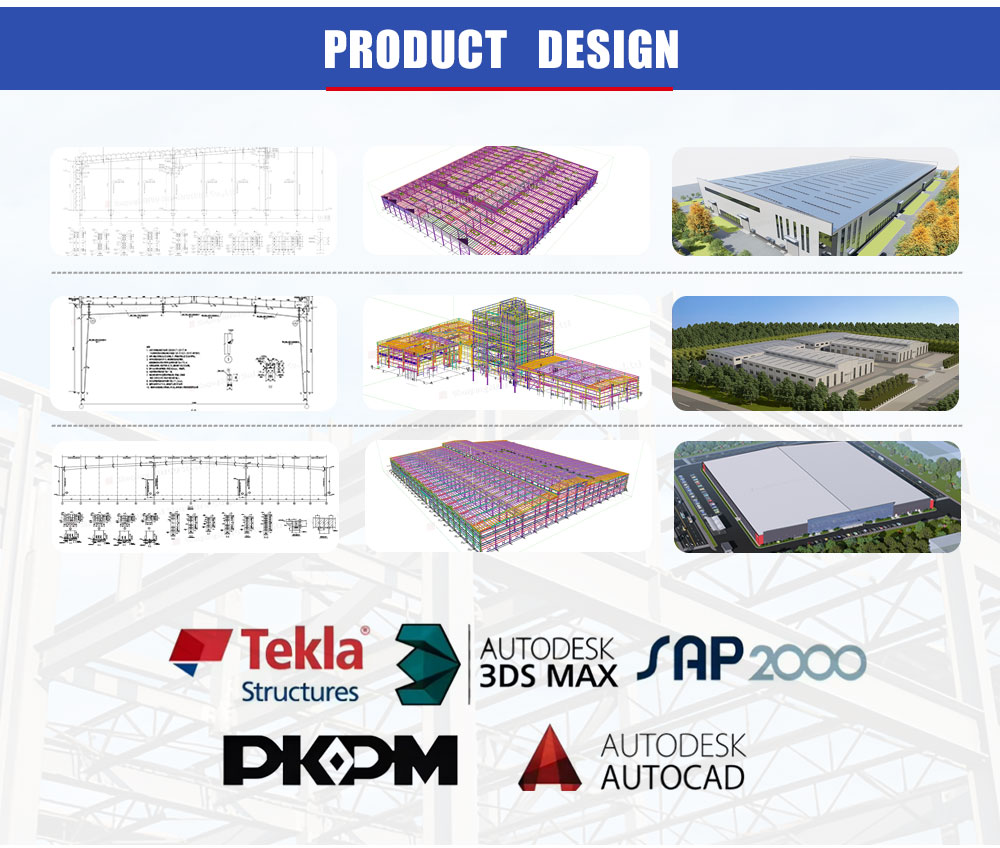

Steel Building Design Service:

MEITUO's team consists of highly skilled and experienced designers who specialize in steel structure solutions. They stay updated on the latest industry trends and technologies, ensuring that our designs not only comply with building codes but also maximize the utility of materials and space for the best project outcomes.

We customize each steel structure project, providing personalized wall panels and materials produced in-house, ensuring the most competitive prices for our clients.

FAQs:

Q: What are the main materials used for prefabricated Steel Structure Warehouse?

A: Prefabricated steel structure warehouse mainly including H-shaped steel, C/Z-shaped steel, color steel plate, rock wool sandwich panel, high-strength bolts, etc.

Q: What are the choices for wall and roof materials of metal beam frame shed?

A: Common materials for metal beam frame shed include single-layer color steel plate, rock wool sandwich panel, glass wool board, polyurethane board, etc.

Q: Can steel frame shed be used for thermal insulation?

A: Yes, you can use rock wool or polyurethane sandwich panels to achieve good thermal insulation performance of steel frame shed.

Q: Is the steel used in structural steel beam anti-corrosion and rust-proof?

A: All our structural steel beam components are treated with sandblasting and rust removal + anti-corrosion coating, and some can also be hot-dip galvanized for anti-corrosion.

About us:

At Shenyang Meituo Steel Structure, we offer intelligent production lines and an experienced team to create high-quality steel structures. Our prefabricated steel structure warehouse products are ideal for warehouses, workshops, exhibition halls, and more, providing lasting solutions for your needs.