Metal Building Cow Farm Steel Structure

Brand MEITUO

Product origin China

1.Steel structure cow house has good ductility and toughness, and can effectively resist natural disasters.

2.Steel structure cow sheds can provide customized services according to needs.

3.Prefab steel cattle farm building uses precise prefabricated components, which can reduce material waste on the construction site and reduce costs.

4.Steel structure shed for cattle farm is in line with the concept of green development.

Product introduction of steel structure cow house:

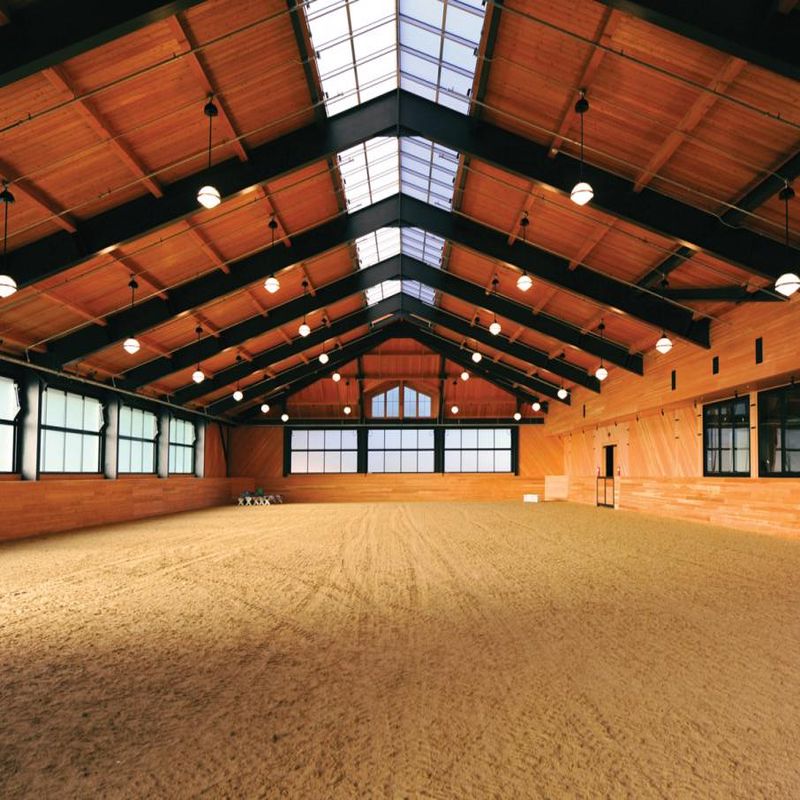

Steel structure cow house is a modern breeding facility building designed for the dairy farming industry. Our steel structure cow sheds use high-strength hot-dip galvanized steel as the main structure, combined with advanced design technology and standardized construction processes to build dairy farms that are easy to manage, stable in structure, and fully functional. The building structure of the prefab steel cattle farm building adopts a modular design, which supports rapid installation and disassembly. And our steel structure shed for cattle farm can provide customized services according to the customer's dairy farming scale and farming process. Prefabricated cattle barn fully considers ventilation, lighting, drainage, manure cleaning, insulation and other functions in the design, which can keep the cattle house dry, clean, and well ventilated, effectively reduce the incidence of diseases, and improve the overall breeding efficiency. The interior of the steel structure shed for cattle farm can be equipped with auxiliary facilities such as cattle pens, feeding channels, manure cleaning systems, water tanks, spray cooling systems, etc. As needed, so that the entire cattle house can be automated and standardized.

Advantages of steel structure cow house:

1. Steel structure cow house is built with high-strength steel, with good tensile, compressive and bending resistance, and the overall structure is stable. The service life of prefab steel cattle farm building can reach 30-50 years. Therefore, steel structure cow house is suitable for areas with frequent natural disasters such as earthquakes, strong winds, and blizzards.

2. Steel structure shed for cattle farm has strong risk resistance and can maximize the safety of livestock. All components of prefabricated cattle barn are prefabricated in the factory and can be assembled on site. Shorten the construction time of steel structure cow sheds.

3. Steel structure cow house adopts reasonable ventilation design, sufficient natural lighting and excellent thermal insulation performance to provide a comfortable living environment for dairy cows. Steel structure cow sheds not only effectively reduce stress response and reduce morbidity, but also increase the milk production of dairy cows.

4. Our prefab steel cattle farm building can be flexibly customized according to different stages and management methods of dairy farming, including the size of the cattle pens, the width of the feeding channel, the method of manure treatment, etc.

5. The building materials of steel structure shed for cattle farm are recyclable, with less pollution and less construction waste, which is in line with the current green and low-carbon development concept. In addition, our prefabricated cattle barn also adopts energy-saving design to reduce energy consumption. Help breeding companies that adopt prefabricated cattle barn to achieve green breeding and clean production.

Product parameters of steel structure cow sheds:

| Structure | Material | Details | |

| Main Structure | Frame Columns and Beams | Q235/Q355 | |

| End Wall Column | Q235/Q355 | ||

| H-beam welding(columns and beams) | Automatic Submerged Arc Welding | ||

| Rust Removal | Shot Blasting | ||

| Surface Processing | Alkyd Paint/Epoxy Zinc Rich Paint/Galvanized | ||

| High-Strength Bolt | Grade 10.9/8.8 | ||

| Common Bolt | Grade 4.8 | ||

| Secondary Structure | Flange Brace | Angle Steel | |

| Horizontal Support | Angle/Round Steel | ||

| Vertical Support | Angle/Round Steel | ||

| Tie Rod | Angle/Round Steel | ||

| Tie Bars | Round Steel/Casing/Shaped Steel | ||

| Purlin | Galvanized Z-beam/C-beam | ||

| Enclosure System | Roofing System | Roofing Materials | 360°Locking Seam System / Locking Screw System / Composite Panel Roofing / Rockwool Maintenance System |

| Daylighting Band | FRP Plate | ||

| Gutter (inside/outside) | Stainless Steel/Colored Steel Plate | ||

| Rain Pipe | PVC Pipe/Color Steel Rainwater Pipe | ||

| Wall System | Wall Materials | Locking Screw System / Composite Panel Wall / Rockwool Maintenance System | |

| Accessories | Sealant, Self-tapping Self-drilling Screws, etc. | ||

| Edge Flashing | Color Plate/Stainless Steel | ||

| Others | Ventilator | Powered/Unpowered Axial Flow Ventilators | Customizable |

| Ventilation Tower | Finished Product | Customizable | |

| Door | Electric Rolling Door/Sliding Door/Fireproof door | Customizable | |

| Window | Aluminum Alloy/plastic Steel Window/Fireproof Window | Customizable | |

Purpose of prefab steel cattle farm building:

Steel structure shed for cattle farm plays an important role in the development of modern agriculture, especially for medium and large dairy farming projects. Our prefabricated cattle barn can provide a safe, comfortable, efficient and environmentally friendly living and production environment for dairy cows, which can effectively reduce the management cost and risk in the farming process.

Steel structure cow house, as a dairy cow house, can provide standardized breeding space. Our steel structure cow sheds can scientifically divide the living areas of dairy cows, such as breeding areas, milking areas, dry areas and calf areas. Prefab steel cattle farm building can make the entire building space open, without the need for internal load-bearing walls, and is convenient for feeding channels, manure cleaning channels, milking areas, etc.

Our steel structure shed for cattle farm is also widely used in the construction of ancillary functional facilities, such as feed storage, hay sheds, equipment rooms, veterinary clinics, etc., which can meet the full process needs of dairy farming.

Prefabricated cattle barn is also widely used in cold or hot areas. Its thermal insulation performance can effectively regulate the temperature in the barn and improve the comfort of dairy cows. Steel structure cow house can also ensure a stable environment in the barn by using automatic ventilation system, spray cooling system and roller curtain insulation equipment, which is conducive to reducing disease transmission and stress response.

The structure and materials of Steel Structure Cow House:

Steel structure cow sheds take full account of the special needs of cattle sheds in terms of structure and material selection. They must be strong and durable, and meet the standards of animal breeding environment. The overall frame of Steel Structure Shed For Cattle Farm is mainly made of high-strength hot-dip galvanized steel, which can remain durable even in a humid and ammonia-containing breeding environment. The walls and roof of Prefabricated Cattle Barn can effectively insulate, waterproof, and rust-proof, and are also easy to maintain. In order to meet the ventilation needs inside the cattle barn, the frame of Prefab Steel Cattle Farm Building reserves sufficient windows and vents, combined with the natural light belt design, so that the air inside the cattle barn can circulate and the light is sufficient.

Why choose our prefabricated cattle barn?

Our prefabricated cattle barn is made of high-quality materials and has strong wind, snow and earthquake resistance. It is very suitable for wind outlets, earthquake zones or rainy areas. The structural stability of prefabricated cattle barn is strong and can generally be used for more than 30 years, which can effectively protect the life safety of dairy cows and equipment assets. In addition, our steel structure cow house has a short construction period and high efficiency, which can meet the needs of customers with requirements for construction time.

Our steel structure cow sheds have high space utilization and flexible internal layout. The steel structure cow sheds have no or few columns in the middle, making the internal space transparent and convenient for large-scale mechanical operations, such as automatic feeding vehicles and manure cleaning vehicles to enter and exit freely, which not only improves efficiency but also reduces labor costs. Our prefab steel cattle farm building can flexibly adjust the layout according to the breeding mode, increase or decrease cattle pens, feeding channels, etc.

The materials of our steel structure shed for cattle farm can be recycled, and there is less construction waste during the construction process, which complies with environmental protection policies. In addition, the prefabricated cattle barn is equipped with natural lighting design, thermal insulation materials and energy-saving equipment, which can effectively reduce energy consumption, reduce carbon emissions from dairy farms, and help create sustainable agriculture.

Frequently asked questions about prefab steel cattle farm building:

1. Can steel structure cow housesh cope with the corrosion of animal excrement and disinfectants?

Our steel structure cow sheds materials have been specially treated and have strong corrosion resistance.

2. Can the span design of steel structure cow sheds meet the needs of large equipment?

We can provide customized services for steel structure cow sheds to meet various needs.

3. Is prefab steel cattle farm building convenient for daily cleaning and epidemic prevention and disinfection?

Our prefabricated cattle barn adopts an optimized design that will not affect daily activities.

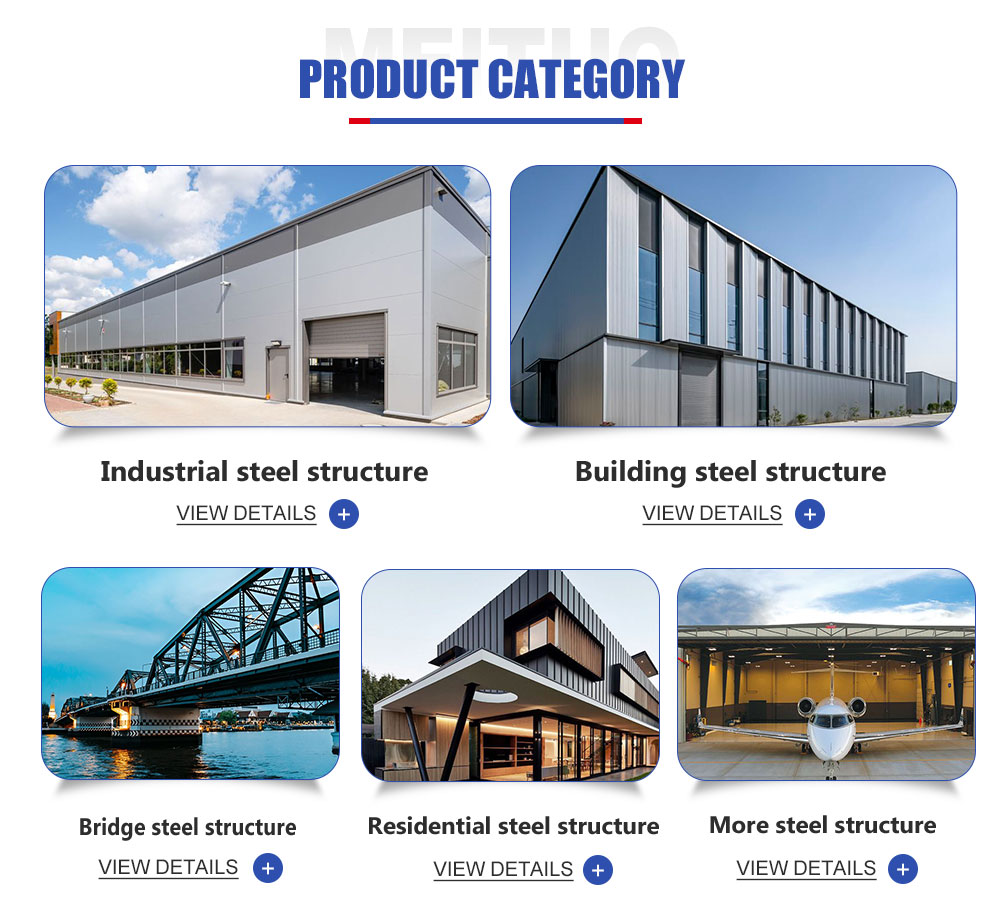

About us:

Meituo is committed to the field of steel structure, and its products cover various types of steel structures such as light steel structure, heavy steel structure, frame structure, box structure, truss structure, steel bridge, container house, etc. It also has 3 modern intelligent steel structure production lines, more than 30 sets of corrugated plate equipment, 2 high-precision c and z-type purlin production lines, and pir green building composite board production line. It is an experienced company.