Meituo Nears Completion of Three Advanced Workshops for Decorative and Eco-Friendly Panels

Meituo Nears Finish on Three High-Tech Facilities for Decorative, Eco-Conscious Panels

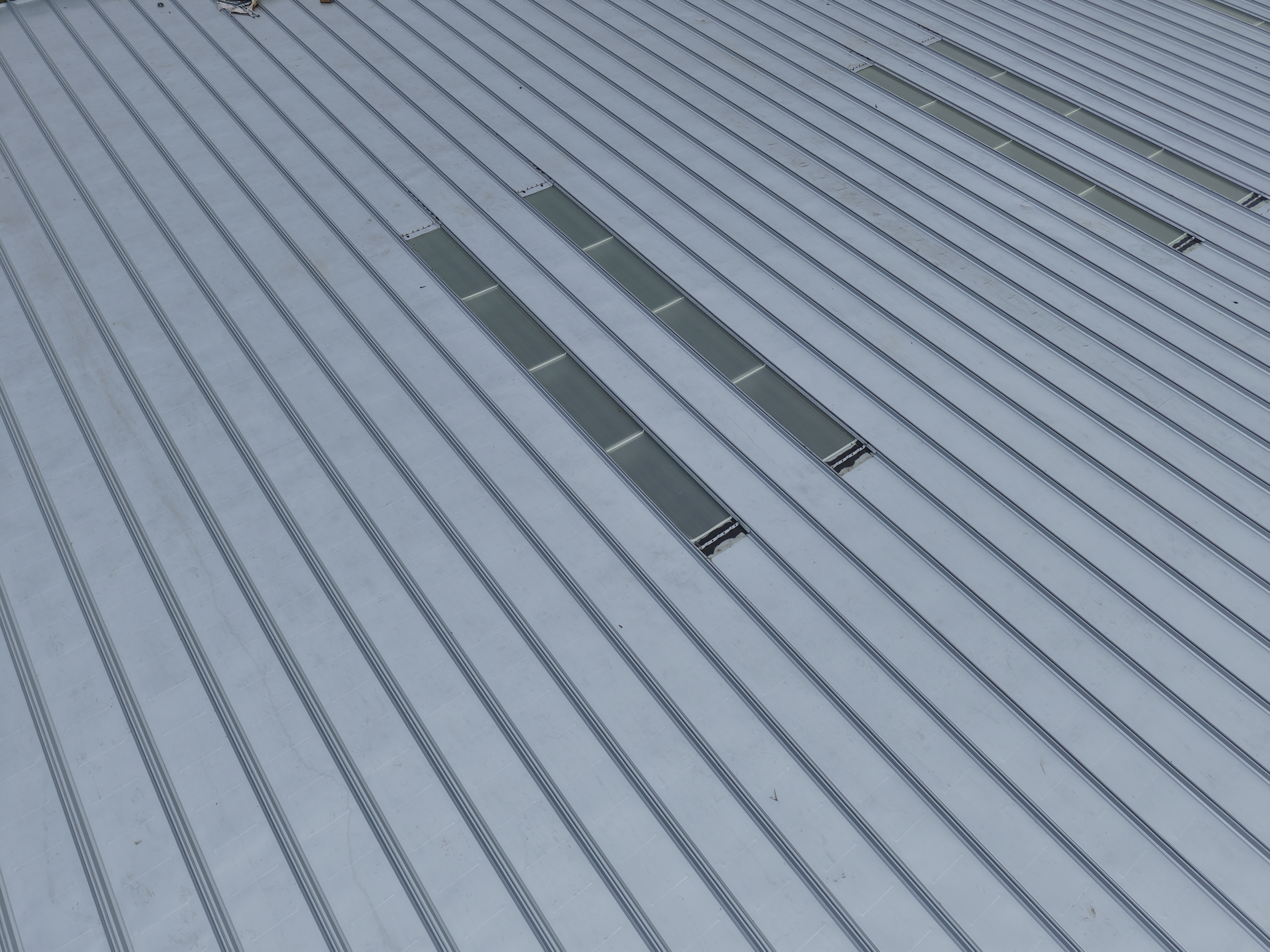

Shenyang, September 2025 — As early morning light spills over Shenyang’s industrial district, it catches the steel skeletons of Meituo’s newest production campus. Three steel-structured buildings—sized at 11,000, 6,700, and 4,500 square meters—are now in the final stretch of construction. When they open, these spaces will focus on making decorative panels and eco-friendly boards, with products bound for markets across the globe.

Inside Meituo’s Upcoming Production Spaces

Walk into Workshop #1, the largest of the three, and the first thing that stands out is how smoothly raw materials move. Sheets of board and steel glide along conveyor belts, stopping first for checks on moisture levels and surface quality. Technicians jot down every measurement, making sure materials meet uniform standards before they head to the finishing steps. The air hums with the sound of automated cutting and sorting tools, and every so often, the crackle of welding cuts through as workers build support frames.

Workshop #2, at 6,700 square meters, is all about refining panel surfaces—and it’s a busy, focused space. Laminating machines add protective coats to panels, while water-based adhesives keep harmful emissions low. Polishing lines and robotic arms tweak each panel with exact precision, leaving surfaces smooth enough to take decorative patterns. What’s clear here is how Meituo balances speed and care: no panel moves forward without passing through several quality checks first.

The smallest building, Workshop #3, is where final inspections and packaging happen. Engineers run through checks for thickness, texture consistency, and color matching on every panel. Once a panel passes, it’s carefully packed up for shipping. Together, the three workshops work like a single, connected system—from the moment raw materials arrive to when finished products leave, efficiency and quality never slip.

Sustainability: A Core Part of the Design

Meituo didn’t just add sustainability as an afterthought—they built it into the workshops from the start. Advanced ventilation systems, dust-collecting equipment, and energy-saving lights cut down on emissions while keeping workers healthy. The team uses water-based coatings and adhesives to lower volatile organic compounds (VOCs), and any scrap material from production gets recycled right on-site. Meituo’s engineers say sustainability isn’t just about following rules—it’s part of how they run day-to-day operations.

The steel frames of the buildings also make future expansion easy. If Meituo needs to reconfigure machines or add new equipment later, they won’t have to make big changes to the structure. That flexibility means the facility can keep up with shifting production needs and new panel designs down the road.

What the New Workshops Mean for Production and Markets

Once fully operational, the three facilities will make thousands of square meters of decorative and eco-friendly panels each month. The products will work for a range of uses: interior wall decor, furniture parts, and panels for modular construction. Clients will also be able to pick from different finishes, colors, and materials that prioritize sustainability.

Industry analysts note that around the world, demand is growing for green building materials and pre-engineered steel-structured industrial spaces. Meituo’s mix of sustainable manufacturing and scalable workshops puts the company in a strong spot to meet both local and global demand efficiently.

Next Steps: From Construction to Full Production

Construction is almost done, and over the next two months, Meituo will finish setting up machinery and training staff. Soon after that, they’ll start pilot production, with plans to reach full capacity by early 2026. For Meituo, these three steel-structured workshops aren’t just new places to make products—they’re a sign of the company’s commitment to top-tier manufactring, caring for the environment, and innovative industrial design.

Looking Ahead: Meituo’s Vision for Responsible Production

When these workshops open, Meituo will be able to make high-quality decorative and eco-friendly panels on a large scale—combining advanced tech with sustainable practices. With its connected workflows, flexible steel design, and focus on getting every detail right, the facility isn’t just a new production hub. It’s an example of what the future of responsible industrial manufacturing can look like.