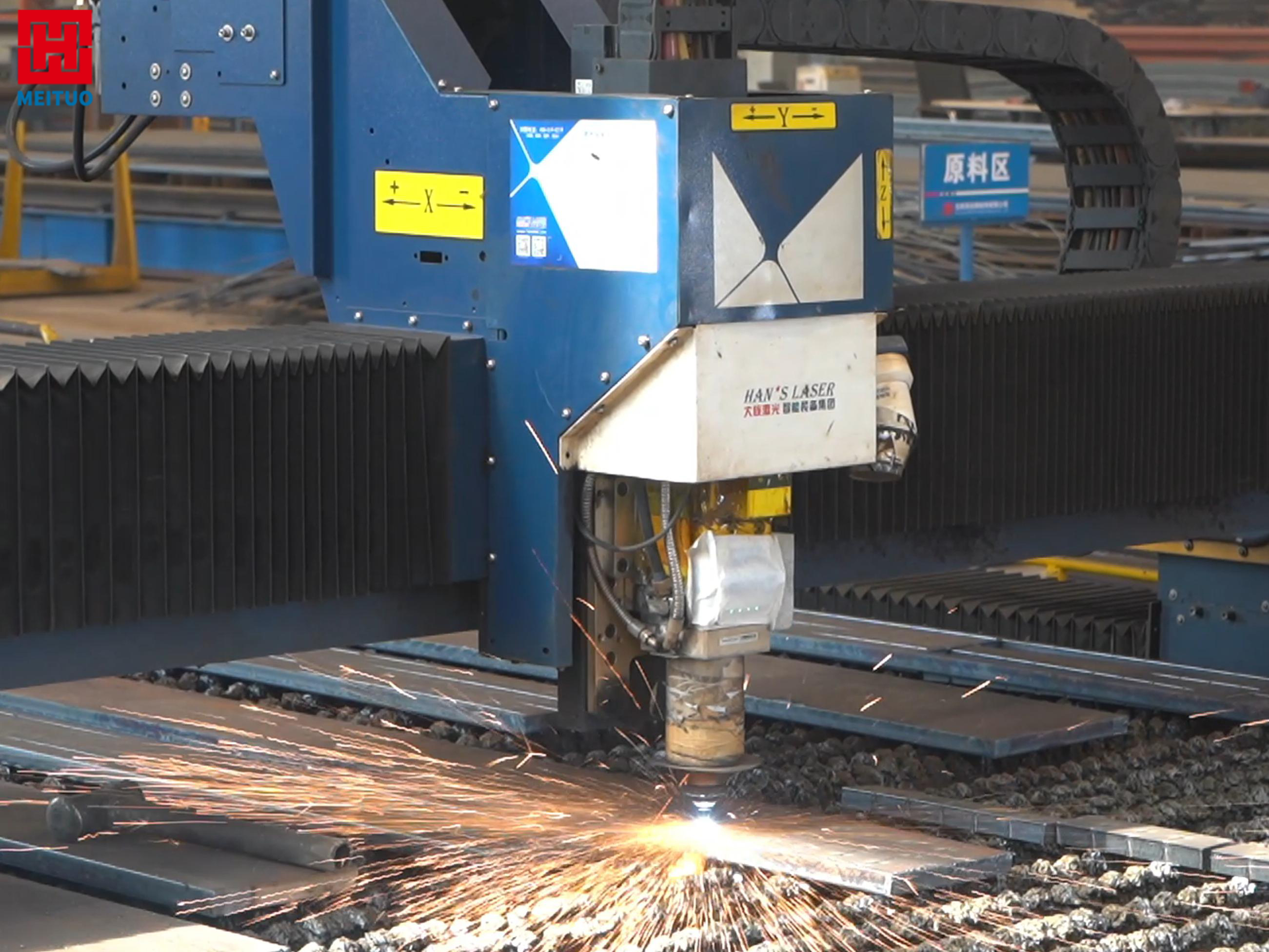

Revolutionizing Precision: Meituo Elevates Steel Structure Fabrication with New Unmanned Fiber Laser Cutting Machine

In the era of Industry 4.0, smart manufacturing defines competitive advantage. Shenyang Meituo Steel Structure Co., Ltd. has always been committed to innovation and is proud to announce that it has fully integrated advanced unmanned fiber laser cutting machines. This significant investment marks a pivotal moment, strategically enhancing our capabilities in future steel structure engineering projects, particularly large-scale steel structure warehouse projects.

Breaking Traditional Limitations: A Leap in Operational Efficiency

Traditional steel structure processing methods, such as flame cutting, plasma cutting, or early CO₂ laser cutting, often face challenges such as precision limitations, inconsistent speed, thermal deformation, material waste, and high reliance on skilled labor. These limitations directly hinder production efficiency and drive up costs for subsequent welding, assembly, and surface treatment. For projects with stringent standards, such as steel structure warehouses, these challenges pose critical bottlenecks.

Shenyang Meituo recognized that only disruptive technological innovation could break through these traditional bottlenecks. After rigorous evaluation, we selected the unmanned fiber laser cutting machine—the pinnacle of modern metal processing technology. This intelligent system integrates optical, mechanical, electronic, and control technologies seamlessly, offering unparalleled advantages:

1. Unmatched speed and throughput:

Unlike traditional processes, which encounter bottlenecks when dealing with complex designs or large-scale production, our fiber laser cutting machine achieves astonishing cutting speeds, significantly increasing throughput. This capability significantly shortens project timelines, particularly critical for steel structure warehouses requiring a large number of standardized components, enabling customers to respond faster to market demands and save substantial time.

2. Sub-millimeter precision for exceptional quality:

The laser beam, with its tiny spot size and high energy density, achieves micron-level cutting precision. This means that complex contours, precise radii, and clean straight edges can be cut with flawless, burr-free results. This inherent precision directly improves component fit, effectively reducing welding deformation and assembly deviations. This fundamentally reinforces the structural integrity and aesthetic quality of all steel structures (including steel warehouses), achieving “millimeter-level precision and lasting strength.”

3. Autonomous operation, optimized resource allocation:

“Unmanned” means highly automated operations achieved through pre-set program sequences and advanced sensor systems, covering automatic material handling, edge detection, layout optimization, and self-diagnostic functions. This not only significantly reduces manual labor and fatigue but also reallocates human resources to higher-value activities such as programming, quality control, and maintenance. Additionally, it effectively reduces human error, ensuring the continuous stability of production processes.