Choosing a Supplier for Steel Buildings: Practical Notes from the Field By Shenyang Meituo Steel Structure Co., Ltd.

Standing up a new plant or storage hub is rarely about the building alone; it’s about throughput, safety, and payback. That’s why many firms now favor steel—fast erection, tidy budgets, and layouts that bend as operations change. Whether you’re planning a steel structure workshop to house production lines or a steel structure warehouse for high-turn inventory, the hard part is picking a partner who won’t let your schedule, or your margins, slip.

1) Start with proof, not promises

Certifications matter, but they’re only the door opener. Ask to see:

material traceability (mill certificates for beams/plates),

weld procedure specs and welder qualifications,

coating/galvanizing reports,

sample shop drawings and a member list,

a packing plan that shows how parts are labeled and loaded.

A reliable team will produce these documents without drama. If they can’t, the risk is yours.

2) Design that earns its keep

Good drawings do more than “make it stand.” In a steel structure workshop, clear spans, crane runway design, and floor loads decide how smoothly equipment moves. For a steel structure warehouse, truck courts, column grids, and racking heights set your hourly throughput. Ask your engineer to show two options: one optimized for capex, one for lifetime cost (energy, maintenance, expansion). When the options are plotted side by side, decisions get easy—and politics stays out of it.

3) Schedule discipline beats heroics

Late steel is expensive steel. Insist on a dated Gantt (design → detailing → fabrication → logistics → site support) and weekly progress snapshots. Automated cutting and drilling help, but so do simple habits: revision control on drawings, barcoding on members, and a single contact who answers within 24 hours. That’s how factories hit handover dates without all-nighters.

4) Price is a headline; total cost is the story

Lowest bid, highest regret—buyers learn this fast. Hidden costs lurk in rework, idle crews, and customs delays. A supplier who bundles design reviews, export paperwork, and installation guidance usually delivers a cleaner project and a lower all-in number. That applies to both a steel structure workshop and a steel structure warehouse.

5) What real references look like

Skip glossy brochures. Ask for three recent jobs of similar tonnage and complexity: shipping photos, site contacts, and punch-list close-outs. If previous clients would buy again, you’re likely safe.

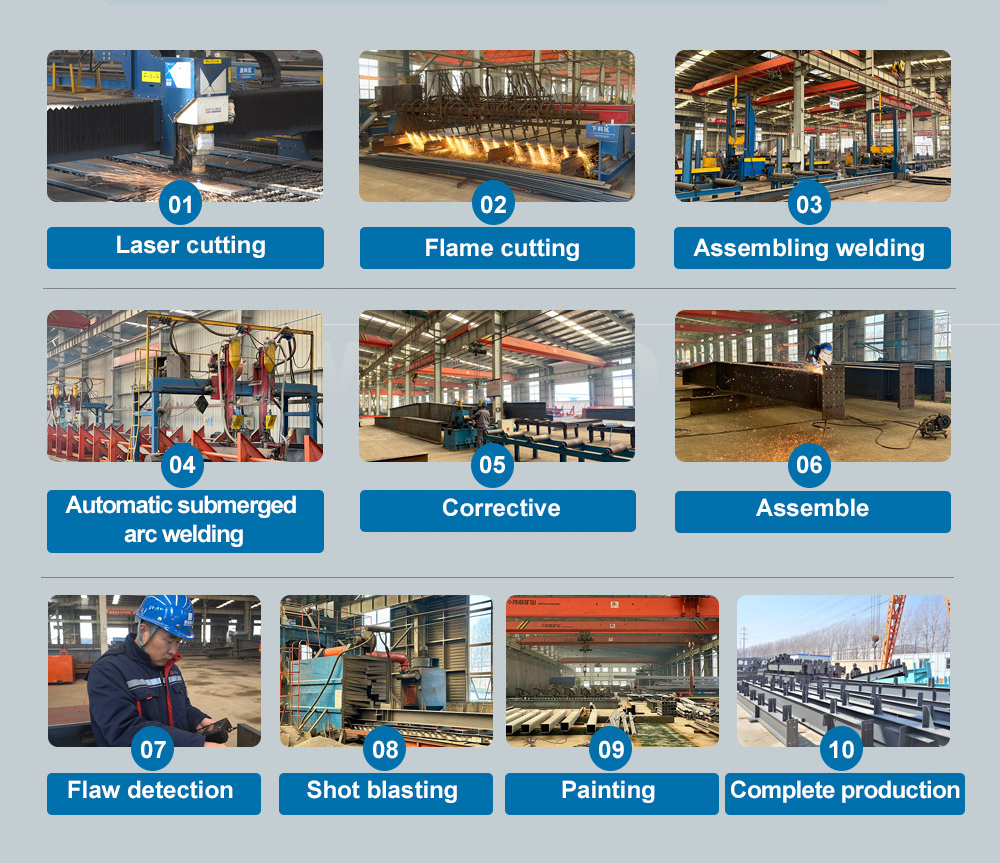

6) Why many companies choose Meituo

Shenyang Meituo Steel Structure Co., Ltd. combines ISO9001/CE-based quality systems with practical export know-how. Our teams prepare alternative layouts, clarify loads early, and issue clean shop drawings so fabrication runs without stop-start waste. For overseas projects, we add packing lists that match the erection sequence and provide remote/on-site guidance to keep cranes, crews, and schedules aligned—whether the brief is a steel structure workshop with cranes or a steel structure warehouse with wide bays and tall racking.

A short checklist you can copy

Scope defined in one page (loads, spans, heights, fire/thermal targets)

Two design options (capex vs. lifecycle) with numbers, not adjectives

Dated program with weekly snapshots

Document set: MTCs, WPS/PQR, coating reports, shop drawings

Packing plan tied to erection order; labels/barcodes match drawings

Named site-support engineer and response SLAs

Closing thought

Buildings don’t create value; operations inside them do. Choose the team that protects uptime, documents the work, and stands up when plans change. If your next project is a steel structure workshop or a steel structure warehouse, make the decision on evidence you can verify—not on slogans you can’t.